TM 55-1520-240-23-6

7-283.2

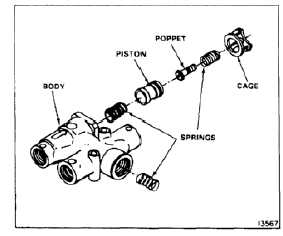

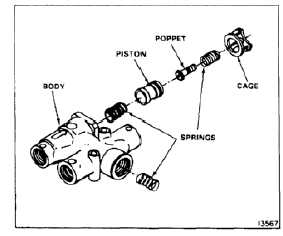

CLEAN AND INSPECT CARGO DOOR PRESSURE ACTUATED VALVE

7-283.2

INITIAL SETUP

Applicable Configurations:

All

Tools:

Technical Inspection Tool Kit, NSN 5180-00-323-5114

Spring Compression Tester

Materials:

Dry Cleaning Solvent (E162)

Personnel Required:

Inspector

Equipment Condition:

Off Helicopter Task

Cargo Door Pressure Actuated Valve Disassembled

(Task 7-283.1)

References:

Task 7-1.1

Solvent (E162) is combustible and

toxic. It can irritate skin and cause

burns. Use only with adequate

ventilation, away from open flame. In

case of contact, immediately flush

skin or eyes with water for at least

15 minutes. Get medical attention

for eyes.

1.

Clean all components with solvent (E162) and

dry thoroughly with clean dry compressed air.

NOTE

General inspection criteria (Task

7-1.1) for obvious damage applies

unless otherwise stated.

Inspection steps cover parts that are

subject to wear.

2.

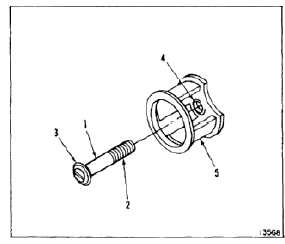

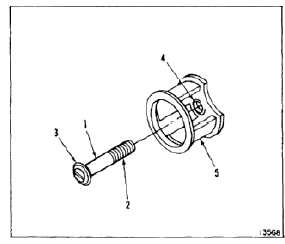

Measure diameter of shank (1) of poppet (2).

Diameter shall not be less than 0.1330 inch.

Inspect shank and spherical seating radius (3)

for nicks, scratches, and signs of wear at contact

area.

3.

Measure diameter of poppet bore (4) of cage (5).

Diameter shall not be more than 0.1405 inch.

7-1053