TM 55-1520-240-23-5

6-166

CONTAMINATION ANALYSIS OF COMBINING TRANSMISSION OIL

6-166

INITIAL SETUP

Applicable Configurations:

All

Tools:

Magnet

Magnifying Glass, 12 Power

Materials:

None

Personnel Required:

Inspector

Equipment Condition:

Off Helicopter Task

1.

Solid particles found in the transmission oil

system may be steel, magnesium, aluminum,

silver, copper, bronze, or fiberglass. Examine

particles as follows:

a.

Separate steel particles. Use a magnet.

b.

Identify and separate remaining particles by

visual inspection.

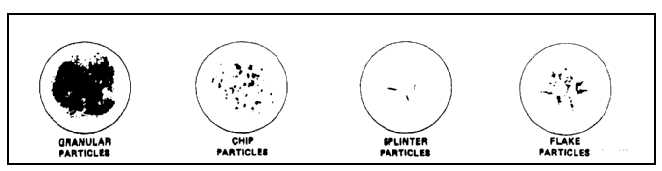

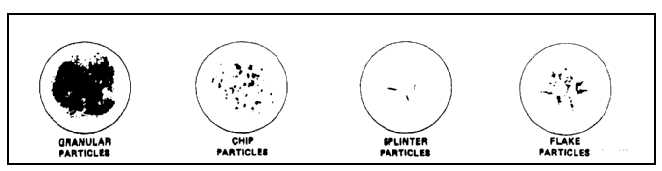

c.

Examine particles with a magnifying glass

to determine shape and condition. Look for

marks or discoloration that may indicate

shearing, burning, or fatigue.

FOLLOW-ON MAINTENANCE:

None

MATERIAL

DESCRIPTION

ACTION REQUIRED

Steel

Fine, hair-like fuzz particles

Normal wear. No action required

Limited amount of splinters, flakes, or

granular particles

Possible failure. Perform serviceability

check (Task 6-170)

Thin flakes up to 1/16 inch in diameter and

1/4 inch long, maximum of 10 flakes

Perform serviceability check (Task 6-170)

Massive amount of splinters, flakes, or

granular particles

Failure. Replace transmission (Tasks 6-72

and 6-77)

Aluminum or magnesium

Granular particles

Perform serviceability check (Task 6-170)

Massive amount of splinters, flakes or

granular particles.

Failure. Replace transmission (Tasks 6-72

and 6-77)

Copper, bronze, or silver

Limited amount of granular particles

Possible indication of bearing cage wear.

Perform serviceability check (Task 6-170)

Massive amount of granular particles or

chip particles

Failure. Replace transmission (Tasks 6-72

and 6-77)

Fiberglass

Granular or fibrous particles

Perform serviceability check (Task 6-170)

END OF TASK

6-563