TM 55-1520-240-23-5

6-91

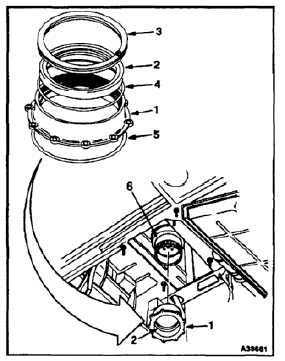

INSTALL AFT TRANSMISSION ROTOR SHAFT SEAL

(Continued)

6-91

1.

Finish seal retainer (1), the metal part of seal (2),

and retaining ring (3) as follows:

The materials used in this step are

flammable and toxic. They can irritate

skin and cause burns. Use only in

well-ventilated area, away from heat

and open flame. In case of contact,

immediately flush skin or eyes with

water for at least 15 minutes. Get

medical attention for eyes.

NOTE

If refinishing materials are not

available, seal the retainer installation

after assembly as in step 6.

a.

Clean parts with acetone (E20) and cloths

(E120). Wear gloves (E184.1).

b.

Wet aged primed surfaces with thinner (E415

or E419). Allow to air dry for no more than

four hours.

c.

Apply two coats of epoxy primer (E292 or

E292.1). Allow to dry.

d.

Apply two coats of epoxy topcoat (E166).

Wear Kevlar gloves (E187) when

handling hot retainer. Hot metal can

burn hands.

Do not heat retainer over 250ºF

(120ºC). Metal can be damaged.

2.

Heat retainer (1) to 230º to 250ºF (110º to

120ºC). Use a gun-type heater and pyrometer.

Wear gloves (E187).

3.

Install packing (4) in retainer (1).

4.

Install seal (2) in retainer (1), flat side up. Use a

wood plank and mallet to seat the seal.

5.

Install retaining ring (3).

6.

If retainer installation components were not

finished in step 1, seal the installation as follows:

Dry cleaning solvent (E162) is

combustible and toxic. It can irritate

skin and cause burns. Use only with

adequate ventilation, away from open

flame. In case of contact, immediately

flush skin or eyes with water for

at least 15 minutes. Get medical

attention for eyes.

a.

Clean exposed top surfaces of the retainer

(1), seal (2) and retaining ring (3). Use dry

cleaning solvent (E162) and cloths (E120).

Wear gloves (E184.1).

b.

Cover retaining ring (3) with a heavy bead

of sealant (E336) from the upper edge of

retainer (1) to the upper surface of seal (2).

7.

Install packing (5) on bottom of retainer (1).

8.

Lightly coat lip of seal (2) with grease (E190) to

prevent corrosion.

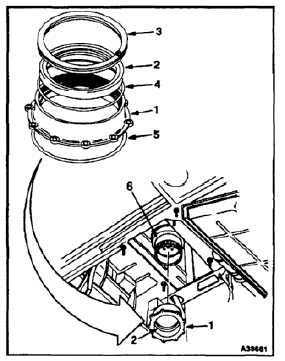

9.

Lightly coat the mating surface of rotor shaft (6)

with oil (E253, E254, or E254.1).

10.

Install seal retainer (1) on rotor shaft (6). Be

careful not to damage seal (2).

6-339