TM 55-1520-240-23-5

6-60

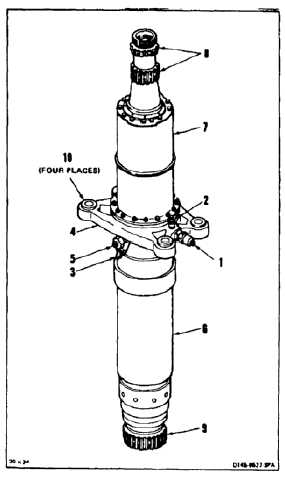

PREPARE AFT ROTOR SHAFT FOR SHIPMENT OR STORAGE

(Continued)

6-60

1.

Install caps on filter (1), pressure switch (2), and

chip detector (3).

2.

Fill support housing (4) with oil (E255) through

union (5). Cap union.

a.

Rotate housing (4) around shaft (6) three

times to spread oil inside housing.

b.

Remove cap from union (5). Drain oil from

housing (4). Install cap on union.

3.

Clean all surfaces of rotor shaft (6). Use dry

cleaning solvent (E162) and clean cloths (E120).

Wear gloves (E186) and goggles. Wear gloves

for the rest of this task.

4.

Clean slider shaft (7), rotor head splines (8),

transmission splines (9) and four bushings (10).

Use fingerprint remover (E175) and clean cloths

(E120).

Touching unpainted surfaces with

bare fingers can cause corrosion.

5.

Put on gloves (E186). Gloves shall be worn for

the rest of this task.

6.

Wipe surfaces cleaned with fingerprint remover

with dry cleaning solvent (E162) and clean cloths

(E120).

7.

Coat slider shaft (7), splines (8 and 9),

and bushings (10) with corrosion-preventive

compound (E153 or E154). Use cloth (E120) to

coat shaft. Use swabbing brush (E86) to coat

splines and bushings.

8.

Cover slider shaft (7), splines (8 and 9), and four

bushings (10) with barrier material (E81) and

tape (E388).

9.

Cover filter (1), pressure switch (2), and chip

detector (3), with barrier material (E51) and tap

(E388).

6-234