TM 55-1520-240-23-4

5-132

INSTALL FORWARD SWASHPLATE

(Continued)

5-132

Swashplate is heavy and can injure

personnel if it drops. Swashplate

must be supported by hoist and

moved carefully to prevent injury to

personnel.

If bearing hits or binds on slider shaft,

bearing surfaces can be damaged.

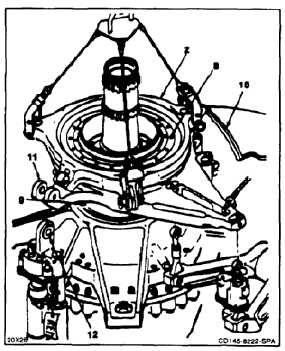

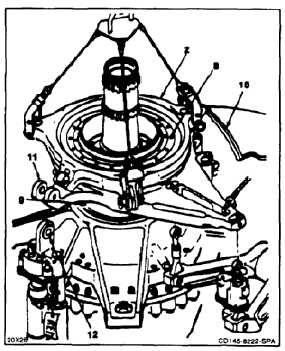

4.

Lift swashplate (2) and guide ball spherical

bearing (8) onto slider shaft (9). Have helper

lower yoke end of swashplate to clear fairing

(10). Guide lugs (11) onto two actuating cylinder

lugs (12).

4.1.

Perform ball spherical bearing friction check

(Task 5-114), spherical ball/spherical ball bearing

axial play check (Task 5-114.1) and swashplate

bearing friction check (Task 5-115).

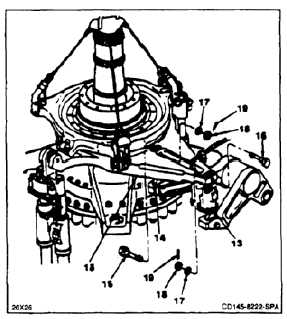

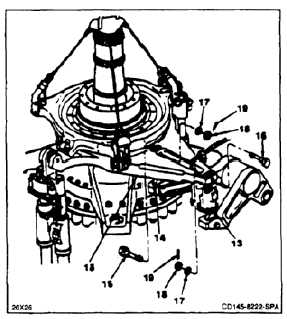

5.

Have helper lift actuator (13) and link (14) and

position in swashplate stationary ring (15).

Install two bolts (16) with heads apart. Install

two washers (17) and nuts (18). Torque nuts to

400 to 660 inch-pounds. (Include cotter pin

installation.) A third washer AN960-816L may be

required for cotter pin alignment.

5-727