TM 55-1520-240-23-4

5-109

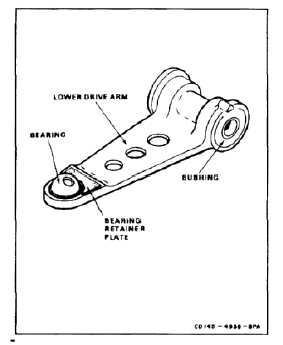

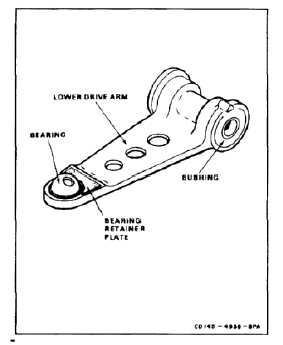

INSPECT LOWER DRIVE ARM

5-109

INITIAL SETUP

Applicable Configurations:

All

Tools:

Technical Inspection Tool Kit, NSN 5180-00-323-5114

Bench Vise

Goggles

Vernier Caliper, 3 Inch

Materials:

Crocus Cloth (E122)

Personnel Required:

Aircraft Powertrain Repairer

Inspector

Equipment Condition:

Off Helicopter Task

NOTE

Procedure is the same to inspect a

forward or aft lower drive arm.

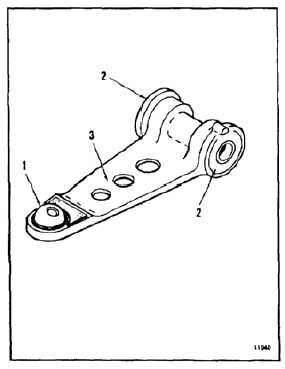

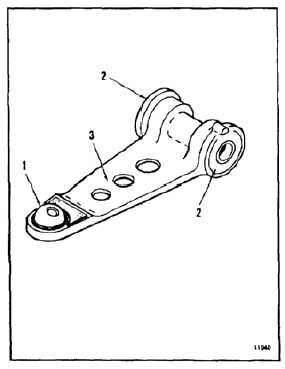

1.

Check Teflon coating on bearing (1). Coating

shall not be torn, scored, or frayed.

2.

Check two shoulder bushings (2) in lower drive

arm (3). Bushings shall not be loose.

3.

Measure inside diameter of bearing (1). Diameter

shall not exceed 0.3755 inch.

4.

Measure inside diameter of bushings (2).

Diameter shall not exceed 0.5647 inch.

5.

Check the bearing surface of each bushing (2)

for damage. Blend out minor surface damage

with crocus cloth (E122). If damage cannot be

blended smooth, reject the drive arm.

6.

Check all surfaces of drive arm (3) for scratches,

pits, or other damage. Damage not exceeding

0.005 inch deep shall be accepted without

rework. Damage between 0.005 inch and 0.040

inch deep shall be blend repaired. Depth of

blend repair shall not exceed 0.040 inch or 10

percent of material thickness, whichever is less.

Blend radius must be at least 1 inch.

5-626