TM 55-1520-240-23-4

5-69.1

REPAIR BLADE FAIRING — FOAM FILLER

(Continued)

5-69.1

APPLY ADHESIVE

NOTE

Prepackaged adhesive (E40) is

preferred. Use adhesive (E41, E43 or

E47.1) only if prepackaged kit is not

available.

18.

Mix tube of adhesive (E40). Follow instructions

on kit.

19.

If adhesive (E40) is not available, prepare

adhesive (E41) as follows:

a.

Weigh 100 parts of resin and 23 parts of

hardener. Use trip balance.

b.

Mix parts in polyethylene cup (E157) until

color is uniform. Use wood spatula (E424).

20.

If adhesive (E43) is used, prepare as follows:

a.

Weigh 7 parts of gray hardener and 5 parts

of white base. Use trip balance.

b.

Mix parts in polyethylene cup (E157) until

color is uniform. Use wood spatula (E424).

21.

If adhesive (E47.1) is used, prepare as follows:

a.

Weigh equal parts of adhesive (E47.1) and

curing agent (E158.1). Use trip balance.

b.

Mix parts in polyethylene cup (E157) until

color is uniform. Use wood spatula (E424).

NOTE

Working life of adhesive is 30

minutes.

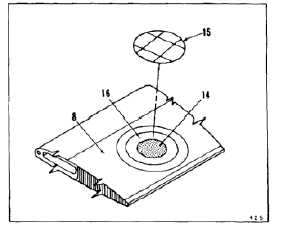

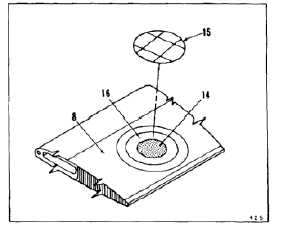

22.

If fiberglass laminate (E168.1) is used, place

patch (15) so that the outer edges curl toward

the blade.

23.

Apply adhesive (E40, E41, E43 or E47.1) to

bottom of patch (15). Use stiff brush.

24.

Apply adhesive to foam plug (14) and bonding

surface (16). Center patch over plug, within

outline. Position patch with fibers at 45º to blade.

Press onto skin (8). If wire mesh diverter damage

is less than 1 square-inch, go to step 26.

5-384