TM 55-1520-240-23-4

5-67.1.1

REPAIR BLADE SHANK VOIDS

(Continued)

5-67.1.1

1.

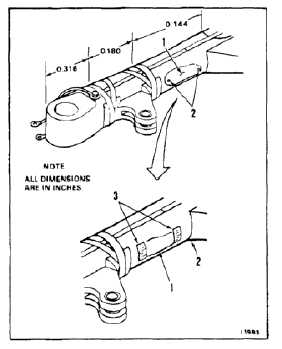

Determine size of void (1). Use coin tapping

(Task 5-63). Outline void area with a marking

pencil (E271).

2.

Drill a hole (2) through unbonded material at

each end of void (1). Do not drill past void. Use a

No. 40 drill bit and a hand drill. Set drill depth so

that the dimensions noted in the illustration will

not be exceeded in the areas shown.

3.

Blow air at no more than 20 psig into one hole

(2). Check that air escapes from the other

hole. If not, drill more holes so that air will pass

through void (1).

4.

Clean void (1). Use acetone (E20) from a plastic

squeeze bottle (E366). Flush void until acetone

runs clear.

Exceeding 20 psig may damage

blade.

5.

Blow clean dry air through void (1) to clear it of

acetone. Do not exceed 20 psig.

6

Prepare an adhesive mixture as follows:

a.

Weigh 2 parts of adhesive (E47.1) and 1

part curing agent (E158). Use a trip balance.

b.

Mix in polyethylene cup (E157). Use wood

spatula (E424).

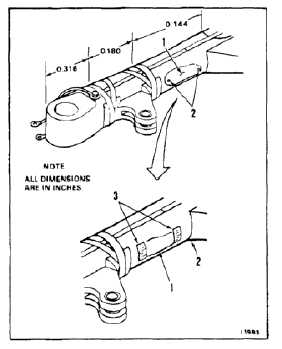

7.

Inject adhesive into void (1) through one hole (2).

Use a hypodermic syringe (E380). When void

is full, shown by adhesive coming out the other

hole, cover all holes. Use tape (E399) (3).

8.

Let adhesive cure for 36 hours at 70º - 80ºF

(21º - 27ºC).

9.

Remove tape (3).

FOLLOW-ON MAINTENANCE:

None

END OF TASK

5-339