TM 55-1520-240-23-4

5-66.2

REPAIR TITANIUM NOSE CAP CRACKS (AVIM)

(Continued)

5-66.2

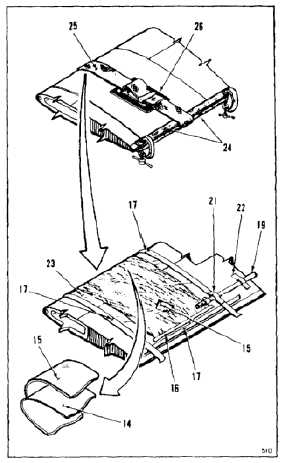

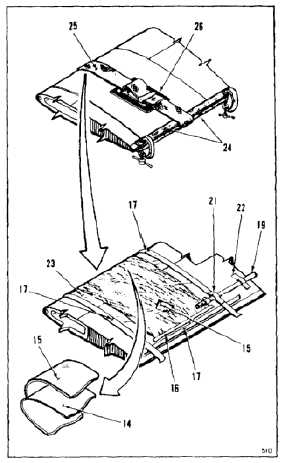

17.

Cure repair at 140º - 160ºF (60º - 71ºC) for 2

hours. Use heat lamps. Monitor temperature.

Use temperature indicating strips (E413). If heat

lamps are not available, go to step 18.

Adhesive will not cure at temperature

below 60ºF (15ºC). Improper cure

can cause bond failure and injury

to personnel. Do not count time at

temperature below 70ºF (21ºC) as

cure time.

18.

Cure repair without heat lamps at 70ºF (21ºC)

for 24 hours.

NOTE

Vacuum source can be removed after

12 hours when repair is cured for 24

hours.

19.

Remove vacuum source. Remove cargo strap

(25), pads (26), wood blocks (24), and polyvinyl

sheet (23). Remove masking tape (22), tube

(19), sealing tape (21 and 17), masking tape

(16), glass cloth (15), and Teflon-impregnated

fabric (14).

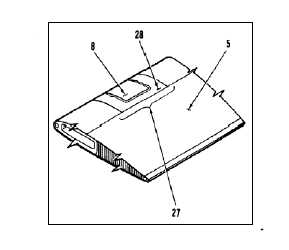

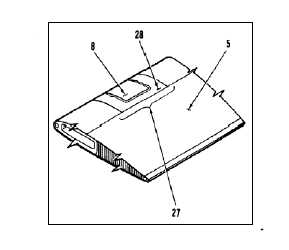

20.

Check repair area (27) for adhesive squeezeout.

Check for voids at areas where there is no

squeezeout.

21.

Apply bead of sealant (E336) (28) around

doubler (8). Blend sealant to form a smooth

gradual fairing from doubler to surface of blade

(5). Cure sealant for 24 hours.

5-317