TM 55-1520-240-23-4

5-43

INSTALL HORIZONTAL HINGE PIN OIL SEALS

(Continued)

5-43

Do not contaminate horizontal hinge

pin bearings. Bearings can be

damaged.

NOTE

Procedure is same to install any

horizontal hinge pin oil seal. There

are six horizontal hinge pin seals on

rotary-wing head. Installation of seals

on forward head is shown here.

Adhesive (E63.1) or sealant (E340.3)

authorized specifically for the

installation of the horizontal hinge pin

seals.

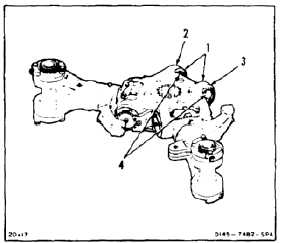

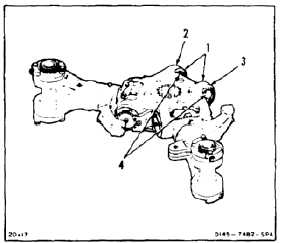

1.

Clean seal seat areas (1) on leading and trailing

lugs (2 and 3). Use cloth (E120) damp with

dry cleaning solvent (E162). Do not wash

contaminants into bearings (4). Wear gloves

(E186).

2.

Clean seals (5). Use cloth (E120) damp with

solvent (E162). Wear gloves (E186).

3.

Check seal lips (6) for nicks or scratches.

NOTE

All sealants and adhesives have

different cure times. When using

sealants and adhesives, the directions

on the container are to be considered

minimum cure time before full

operation of the aircraft.

4.

Apply thin, even coat of adhesive (E63.1) or

sealant (E340.3) to seal seats (1) and metal

outside diameter of seals (5). Wear gloves

(E186).

5.

Install bearing and seal pusher (T6) (7) on trailing

lug (3) as follows:

a.

Install seal pilot (8) on bolt (9).

b.

Position seal (5) on bearing and seal pilot

(10) with seal lips (6) facing away from pilot.

c.

Position bearing and seal pilot (10) and seal

(5), on inboard side of lug (3).

d.

Install bolt (9) in bearing and seal pilot (10).

5-185