TM 55-1520-240-23-4

5-39

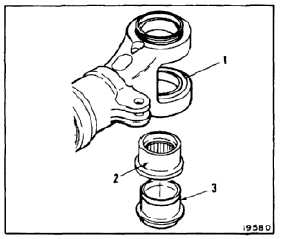

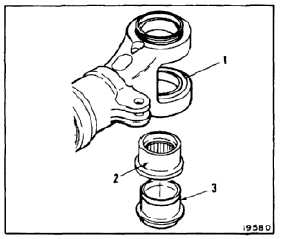

INSTALL VERTICAL HINGE PIN BEARING

(Continued)

5-39

1.

Clean lug (1), bearing outer race (2), and bearing

inner race (3). Use cloth (E120) damp with

solvent (E162). Remove tag, if tied to bearing.

Use gloves (E186).

Do not exceed 250ºF (121ºC) when

heating lug. Lug will be damaged.

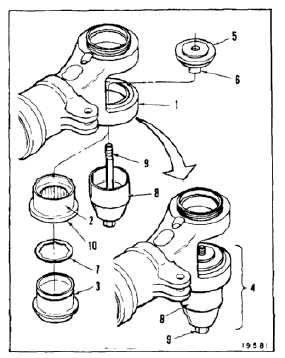

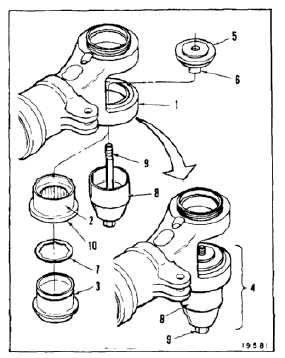

2.

Heat lug (1) to 240ºF (116ºC). Use heater gun.

Use temperature indicating strips (E413) to

monitor temperature. Wear gloves (E187).

3.

Install bearing and seal puller (T10) (4) as

follows:

a.

Position base (5) on lug (1) with boss (6)

down.

b.

Lubricate outside of outer race (2). Use

lubricating oil (E254).

c.

Inspect thrust washer (7) for cracks,

distortion, gouges, scoring, nicks and

scratches. If cracks, scoring or distortion are

found, reject the washer. Gouges, nicks, or

scratches less than 0.002 inch deep may be

polished out, provided a minimum thickness

of 0.1755 inch is not exceeded.

d.

Position thrust washer (7) on inner race (3).

Position outer race (2) on inner race. Position

bearing assembly on driver (8).

e.

Position bolt (9) through lug (1). If bearing (3)

is not being rotated, align matchmaker on

outer race (2) and lug.

f.

Install bolt (9) through base (5).

4.

Install bearing assembly by tightening bolt (9)

until shoulder (10) is seated.

5.

Remove bolt (9), base (5), and driver (8).

INSPECT

5-172