TM 55-1520-240-23-4

5-21.3

INSPECT ROTOR HUB SURFACE

(Continued)

5-21.3

NOTE

Procedure is same for forward and

aft heads.

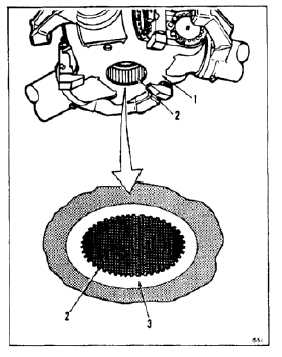

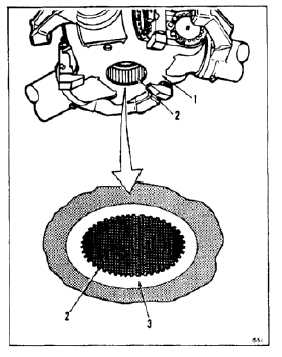

1.

Position head (1) so that splines (2) on underside

are accessible.

2.

Remove lacquer finish from a 1 inch wide strip

(3) around splines (2). Use acetone (E20) and

clean cloths (E120).

3.

Remove primer coat to bare metal from strip

(3). Use abrasive pads (E2) and acetone (E20).

Wear gloves (E186).

4.

Rinse finish removal area with a clean cloth

(E120) soaked in water. Dry area with a clean

dry cloth.

5.

Perform fluorescent-penetrant inspection of

strip (3) around splines (2). (Refer to TM

1-1500-335-23.) There shall be no cracks. If a

crack is suspected, refer to TM 1-1520-253-23.

6.

If no cracks are found, remove inspection

coating. (Refer to TM 1-1500-335-23.)

7.

Refinish strip (3) as follows:

a.

Apply one coat of wash primer (E302). Wear

gloves (E186). Let air dry for 1 hour. Do not

let dry more than 4 hours.

b.

Apply one coat of fast drying primer (E294).

Wear gloves (E186). Let air dry for 1 hour.

Do not let dry more than 2 hours.

Lacquer (E213) is extremely

flammable. It can be toxic. Keep away

from heat, sparks, or open flame. In

case of contact, immediately flush

skin or eyes with water for at least

15 minutes. Get medical attention

for eyes.

c.

Apply two coats of black lacquer (E215).

Wear gloves (E186). Let air dry 1 hour

between coats.

FOLLOW-ON MAINTENANCE:

None

END OF TASK

5-110