TM 55-1520-240-23-1

1-90

LUBRICATE SWASHPLATE

(Continued)

1-90

NOTE

Lubricate forward or aft swashplate

in the same way.

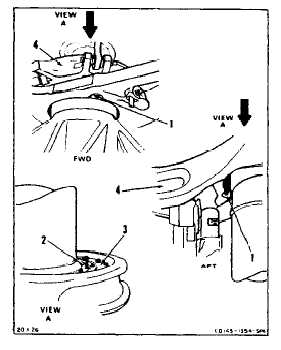

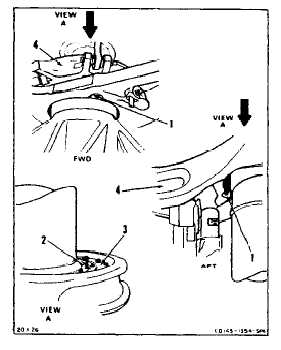

1.

Using a clean lint free cloth (E134.1) dampenend

with cleaning solvent (E471), clean the inner

ring assembly and the outer ring assembly at

the upper seal (2 and 3). Wipe dirt and grease

from lubrication fitting (1). Ensure all surface grit,

sand, and other foreign materials are removed.

Rotary-wing blades can seriously

injure personnel. Make sure area

around helicopter is clear of personnel

before turning blades.

Pumping grease into swashplate

without turning rotating ring can result

in bearing damage.

NOTE

If you cannot pump and turn at the

same time, turn ring in 12 equal

steps, 30° each step. Pump in grease

between steps.

2.

Have helper rotate ring (4) by pulling blades

around with tiedown line. As ring rotates, pump

grease (E190) into fitting (1). Use a hand

lubricating gun with a flexible coupling.

NOTE

A minimum of 16 ounces of grease

must be used to adequately purge

grease from the swashplate.

3.

Pump until clean grease appears all the way

around the line between stationary seal (2) and

rotating seal (3).

4.

Wipe grease from fitting (1) and between seals

(2 and 3).

5.

Feel for metal chips in seal grease. If there are

chips, replace swashplate (Tasks 5-115 and

5-132 or Tasks 5-116 and 5-133).

NO BREAK - WORK HARDER

NO BREAK - WORK HARDER

FOLLOW-ON MAINTENANCE:

Close left forward transmission fairing (Task 2-2).

Close left pylon work platform (Task 2-2).

END OF TASK

1-324 Change 1