TM 55-1520-240-23-1

1-57

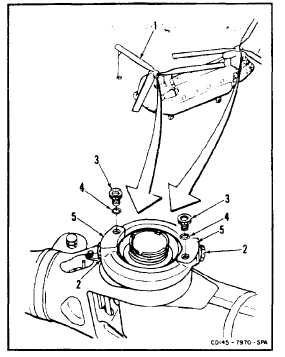

SERVICE VERTICAL HINGE PIN OIL TANKS (Continued)

1-57

CAUTION

Under normal conditions rotary heads

shall be serviced with only one type

of oil (E254 or E254.1). Oil (E254)

must be used for temperatures below

-25 F (-32 C) .

NOTE

Procedure is same to service vertical

hinge pin oil tanks on any pitch

varying housing. Upper and lower

tanks are connected by manifold tube

and are serviced together.

1.

Position blade (1) to level sight indicators (2). Tie

down one forward and one aft blade (1).

WARNING

Prolonged oil leakage can damage

finish and create a work hazard

by making the fuselage slippery. It

can also affect other systems in the

helicopter. Therefore, good judgment

must be used when determining

allowable leakage.

NOTE

If oil level in sight gage drops from full

(half-way) mark to bottom of glass in

two hours of operation, leakage is too

great. Check for source of leakage.

Repair as required.

2.

Check oil level in two sight indicators (2).

3.

Remove lockwire. Remove two filler/drain plugs

(3) and packings (4) from upper tank (5).

4.

Service tank (5) until oil reaches center of sight

indicators (2). Use lubricating oil (E254 or

E254.1) and funnel. Wear gloves (E184.1).

5.

Install packings (4) and plugs (3). Torque plugs

to 85 inch-pounds.

1-222