TM 55-1520-240-23-5

6-10

INSPECT DRIVE SHAFTING ON AIRCRAFT (Continued)

6-10

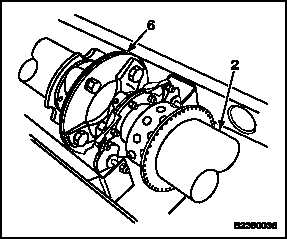

h.

Cracks in plates (6). Use a 5X magnifying

glass to check. If a crack is suspected in

drive shaft plate, refer to TM 1-1520-253-23.

i.

Nicks on inside edge of plates (6). Use a

pointed scribe to check.

j.

Cracks, nicks, scratches, or gouges in dents

in tube (2). Use a 3X to 5X magnifying glass

for inspection. If a crack is suspected in drive

shaft tube, refer to TM 1-1520-253-23.

NOTE

Vibro-engraved factory markings on

tube are allowed.

k.

Inspect for corrosion. If found, perform Task

6-10.1.

2.

Inspect for nicks, scratches, or gouges in tube (2)

and plates (6). Repair damage (Task 6-11).

3.

Visually inspect tubes (2) for circumferential

scoring. Observe following limits:

a.

Depth after blending: 0.010 inch maximum.

b.

Length after blending: 2.0 inches maximum.

c.

Width after blending: 0.40 inch maximum.

d.

Minimum distance from adapter rivets is: 7

inches each end.

e.

Minimum axial distance between

circumferential scoring repair is 4.5 inches.

f.

Maximum of one circumferential scoring

repair around tube OD at any one point.

Change 1

6-31