TM 55-1520-240-23-9

11-241

INSTALL TUNNEL CONTROL ARMS (Continued)

11-241

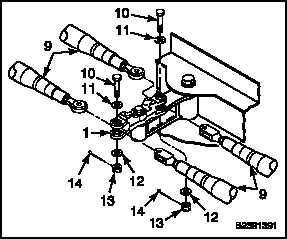

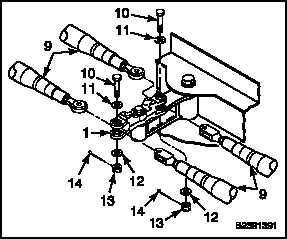

4.

Position four connection links (9) in control arm

(1).

5.

Install two bolts (10), two washers (11), and

two nuts (13). Torque two nuts 60 to 90

inch-pounds. Install two cotter pins (14).

6.

Check bolts (10). Bolts shall not rotate with

torque less than 10 inch-pounds. Bolts shall

have no axial looseness. If bolts rotate or are

loose, add washer under nut and repeat step 5.

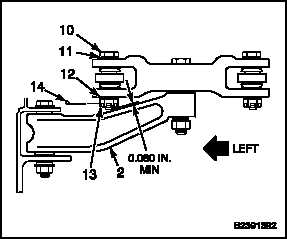

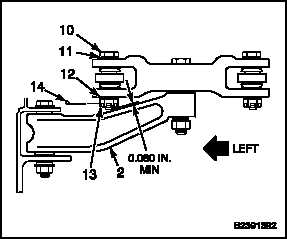

7.

Check clearance between bolt (10) and idler

(2). Clearance shall be 0.060 inch minimum. If

clearance is more than 0.060 inch, go to step 11.

If clearance is less than 0.060 inch, go to step 8.

WARNING

Epoxy primer (E292.1) is flammable

and toxic. It can irritate skin and

cause burns. Use only with adequate

ventilation, away from heat and

open flame. Avoid contact with skin,

eyes, or clothing. In case of contact,

immediately flush skin or eyes with

water for at least 15 minutes. Get

medical attention for eyes.

8.

Remove cotter pin (14), nut (13), two washers

(12 and 11), and bolt (10). Burnish idler (2) under

bolt hole. Use abrasive paper (E11). Do not

burnish more than 0.040 inch deep and 1 inch in

diameter. There shall be no sharp indentations

or gouges in burnished area. Touch up burnished

area with two coats of epoxy primer (E292.1).

Wear gloves (E184.1).

9.

Install bolt (10), two washers (11 and 12) and nut

(13). Torque nut to 60 to 90 inch-pounds.

10.

Install cotter pin (14). Turn ends of cotter pin

into nut castellations to maintain 0.060 inch

clearance.

11.

Check bolt (10). Bolt shall not rotate with torque

less than 10 inch-pounds. Bolt shall have no

axial looseness. If bolt rotates or is loose, add

washer under nut and repeat steps 9 and 10.

11-937