TM 55-1520-240-23-9

11-187

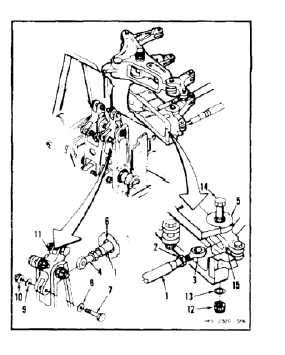

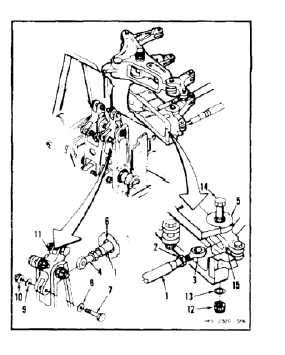

INSTALL MIXING LINKAGE CONNECTING LINKS

(Continued)

11-187

Make sure bushings are in bellcranks

before installing bolts or component

damage will result.

To obtain proper clamp-up and

prevent damage to controls, if a light

washer is used under nut, prior to

applying torque make sure the washer

does not hang up in the bolt retaining

feature groove.

NOTE

Impedance bolts are installed in flight

control connections. These bolts are

self-retaining and require a special

nut and torque (Task 1-13).

INSTALL LOWER OUTBOARD LINK

1.

If lower outboard link (1) is a replacement, loosen

nut (2). Turn rod end (3) 90º to rod end (4).

Torque nut (2) to 350 inch-pounds.

2.

Insert link (1) through bellcrank (5) and access

hole.

3.

Remove bolt (7), washer (8 and 9), and nut (10)

from bellcrank (11).

FLIGHT SAFETY PARTS

This is an installation critical flight

safety part. All aspects of its assembly

and installation must be ensured.

Ensure that both rod end jam nuts are

installed and torqued.

Ensure that the rivet through the fixed

rod end bearing is secure.

Ensure larger diameter bore rod end

bearing is facing aft.

Ensure proper attaching hardware

(impedance type bolt, nut, and

washers) is installed including

verification of bolt head orientation,

torque, and installation of cotter pins.

Loose attachments within flight control

primary linkage will degrade aircraft

control. Missing components will

cause loss of control.

4.

Position link (1) in bellcrank (11). Install bolt (7),

washers (8 and 9), and nut (10) in bellcrank. Do

not torque nut at this time. Remove tag.

5.

Remove nut (12) and washer (13) from bolt (14).

6.

Raise bolt (14) from bellcrank (5). Position link

(1) in bellcrank (15).

7.

Install bolt (14), washer (13), and nut (12). Do

not torque nut at this time.

11-737