TM 55-1520-240-23-9

11-124

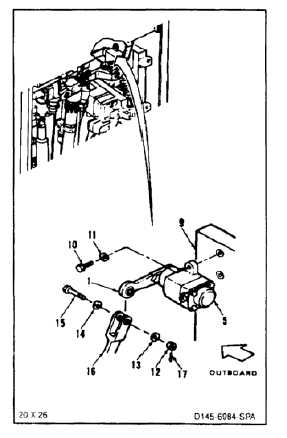

INSTALL THRUST VISCOUS DAMPER

(Continued)

11-124

FLIGHT SAFETY PARTS

This is an installation critical flight

safety part. All aspects of its assembly

and installation must be ensured at

each joint connection and mounting to

the airframe.

Ensure that the correct damper is

installed in the thrust axis. Incorrect

axis orientation will adversely affect

force feel damping characteristics of

the flight control system.

Ensure the proper damper arm

assembly is installed. Arm assembly

has shear rivets sized to specific load

requirements in the event of a damper

failure.

Ensure all hardware mounting the

damper assembly to the pallet

assembly is secure and that there is

no evidence of loose pallet inserts.

Loose attachments within flight control

secondary linkage will degrade

aircraft control, missing components

may cause loss of control.

Bushing must be link before installing

bolt; otherwise, damage to component

will result.

NOTE

Impedance bolts are installed in flight

control connections. These bolts are

self-retaining and require a special

nut and torque (Task 1-13).

7.

Position damper (5) on pallet (9), arm (1)

outboard. Install two bolts (10) and washers (11)

in damper.

7.1.

Torque bolts (10) to 23 inch-pounds.

8.

Remove nut (12), two washers (13 and 14) and

bolt (15) from link (16).

9.

Position arm (1) in link (16). Install bolt (15), two

washers (14 and 13), and nut (12) in link and

arm.

10.

Torque nut (12) to 15 to 25 inch-pounds. Install

cotter pin (17).

11.

Check bolt (15). Bolt shall not rotate with torque

less than 10 inch-pounds. There shall be no

axial looseness. If bolt rotates or is loose, and

washer under nut and repeat step 10.

INSPECT

FOLLOW-ON MAINTENANCE:

Perform thrust control operational check (TM

55-1520-240-T).

Install closet backup panel (Task 2-2).

Install closet acoustic blanket (Task 2-108).

END OF TASK

11-576