TM 55-1520-240-23-9

11-100

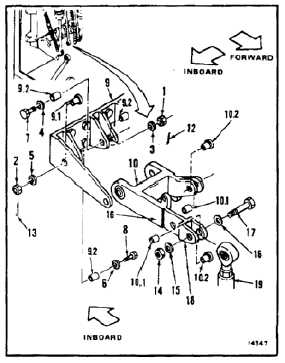

INSTALL PITCH IDLER BELLCRANK

(Continued)

11-100

Bushings must be in bellcranks and

links before installing bolts; otherwise,

damage to components will result.

NOTE

If a crack in the connecting link,

bellcrank, or support is suspected

during installation, refer to TM

1-1520-253-23.

NOTE

Impedance bolts are installed in flight

control connections. These bolts are

self-retaining and require a special

nut and torque (Task 1-13).

1.

Remove two nuts (1 and 2), four washers (3, 4, 5,

and 6) and two bolts (7 and 8) from support (9).

1.1.

Remove bushings (9.1 and 9.2) from support

(9). Clean bushings and bores with dry cleaning

solvent (E162) and clean cloth (E120). Wear

gloves (E184.1) and goggles.

1.2.

Coat bushings (9.1 and 9.2) with epoxy primer

(E292). Install bushings wet in support (9).

FLIGHT SAFETY PARTS

This is an installation critical flight

safety part. All aspects of its assembly

and installation must be ensured at

each joint connection and mounting to

the airframe.

Ensure that all bushings and bearings

are properly installed (including

bushing orientation) in each input and

output clevis of the idler.

Ensure hub bearings are serviceable

and properly installed.

Ensure proper attaching hardware

associated with all components

mounted to this idler assembly and the

idler assembly itself (impedance type

bolt, nut, and washers) is installed

including verification of bolt head

orientation, torque, and installation

of cotter pins.

Loose attachments within flight control

secondary linkage will degrade

aircraft control. Missing components

will cause loss of control.

2.

Position pitch idler bellcrank (10) in support (9),

arm (11) forward and inboard. Install two bolts

(7 and 8), four washers (6, 5, 4, and 3), and two

nuts (1 and 2), in support.

3.

Torque two nuts (1 and 2) to 30 to 45

inch-pounds. Use wrench and dial indicating

scale. Install two cotter pins (12 and 13).

4.

Check bolts (7 and 8). Bolts shall not rotate with

torque less than 10 inch-pounds. There shall be

no axial looseness, if bolt rotates or is loose, add

washer under nut, and repeat step 3.

INSPECT

5.

Remove nut (14), two washers (15 and 16), and

bolt (17) from lugs (18) of bellcrank (10).

5.1.

Remove bushings (10.1 and 10.2) from bellcrank

(10). Clean bushings with dry cleaning solvent

(E162) and clean cloth (E120). Wear gloves

(E184.1) and goggles.

5.2.

Coat bushings (10.1 and 10.2) with epoxy primer

(E292). Install bushings wet in bellcrank (10).

6.

Position pitch input connecting link (19), between

lugs (18) of bellcrank (10). Install bolt (17), two

washers (16 and 15), and nut (14). Do not torque

nut at this time.

11-520