TM 55-1520-240-23-8

10-32

TEST AFT FUEL TANK AFTER INSTALLATION

(Continued)

10-32

4.

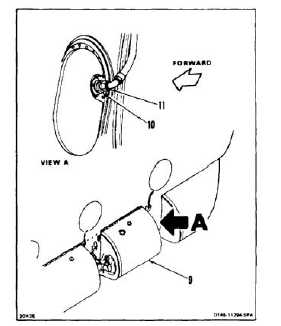

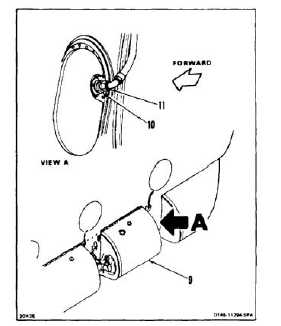

At aft end of tank (9), hold fitting (10) with wrench

and disconnect hose (11). Plug hose.

5.

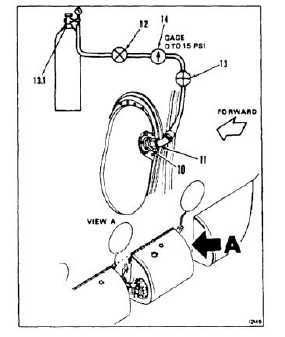

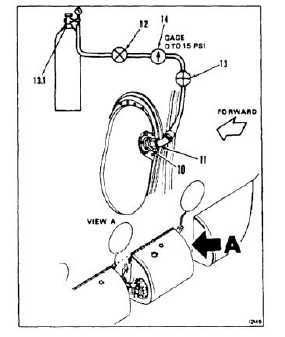

Make sure valve (12) is open and valve (13) is

closed. Connect test setup to fitting (10).

Structural damage to aircraft may

occur if more than 4.0 psi is applied.

5.1.

Open nitrogen or air supply source (13.1) and

regulate pressure to 3.0 psi. Do not apply more

than 4.0 psi.

6.

Open valve (12) and allow pressure to stabilize

at 3.0 psi. Close valve. Do not apply more than

4.0 psi.

7.

Wait 15 minutes. Check gage (14). If gage

indicates 3.0 psi, go to step 14. If age indicates

less than 3.0 psi, go to step 8.

CHECK FOR LEAKS OUTSIDE OF TANK

8.

Check for leaks as follows:

a.

Check test setup connections upstream

and downstream of valves (12 and 13), and

gage. Use mixture of soap (E353) and water,

and brush (E85). Allow system to remain

under pressure for 15 minutes. If bubbles

grow in size, connection is leaking. Tighten

leaking connections or replace packings as

needed. Also check all joints, seams, and

cast components. If leak is found, repeat

steps 6 and 7.

10-152