TM 55-1520-240-23-6

7-98

TEST PITCH, ROLL, YAW, OR THRUST INTEGRATED LOWER CONTROL ACTUATOR

(ILCA) (AVIM) (Continued)

7-98

326.

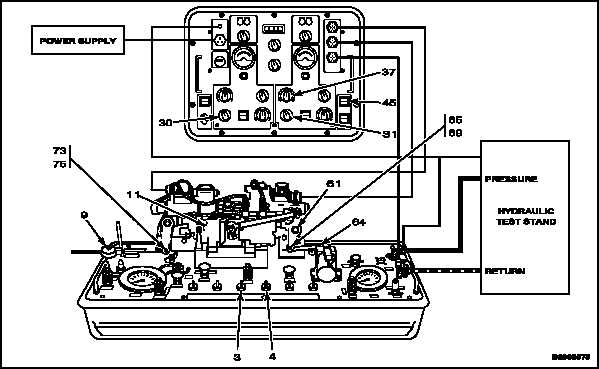

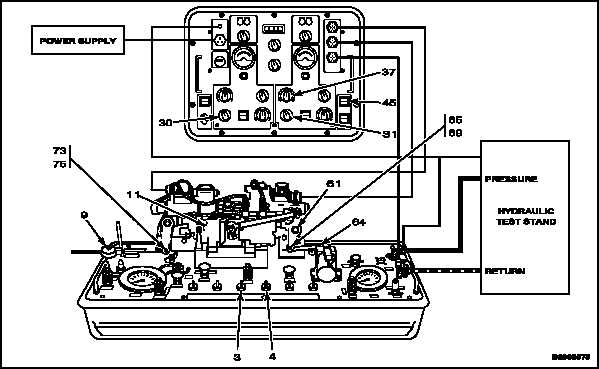

Set SAS 2 FUNCTION SELECT switch (31) to

SQ WAVE.

327.

Set SAS 2 SQ WAVE control (37) to MIN.

328.

Set SAS PRESS SYS 2 valve (4) to PRESS.

329.

Slowly turn SAS 2 SQ WAVE control (37) toward

MAX until indicator (9) indicates about 0.30 inch

travel.

329.1. Allow link to complete 50 cycles minimum.

Check for 1 drop per 50 cycles at the extensible

link output seal.

NOTE

If leakage exceeds 1 drop in 50

cycles, replace seals or extensible

link.

330.

Set SAS 2 FUNCTION SELECT switch (31) to

CLSD loop.

331.

Set SAS PRESS SYS 2 valve (4) to VENT, then

OFF.

332.

Remove PIN 2 (69) from arm (61) and stow.

333.

Unstow cycle motor linkage (64). Position linkage

in input arm (61).

334.

Remove PIN 1 (65) from stowage. Install PIN 1

(65) in arm (61) and linkage (64).

NOTE

Bring cycle motor arm bearing into

alignment with input arm from above.

335.

Remove and stow indicator (9), PIN 3 (73), and

bearing (75).

336.

Set SAS PRESS SYS 1 valve (3) and SAS

PRESS SYS 2 valve (4) to PRESS.

337.

Set SAS 1 FUNCTION SELECT switch (30) and

SAS 2 FUNCTION SELECT switch (31) to SQ

WAVE.

338.

Press CYCLE MOTOR switch (45) ON. Run cycle

motor for 15 minutes. Then run it for 50 cycles.

NOTE

Motor runs at about 20 cycles per

minute. 50 cycles take about 2.5

minutes.

339.

Check actuator (11) for leaks. Dynamic seals

shall not exceed 1 drop in 50 cycles. There

shall be no leaks at static seals or relief valves.

NOTE

If leakage exceeds 1 drop in 50

cycles, replace seals.

7-466

Change 1