TM 55-1520-240-23-6

7-339

BLEED UTILITY HYDRAULIC CARGO RAMP AND DOOR SYSTEM

(Continued)

7-339

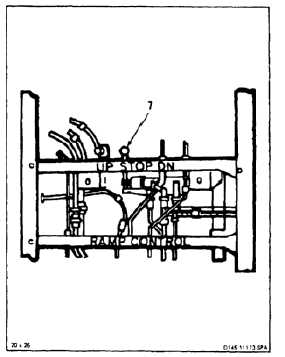

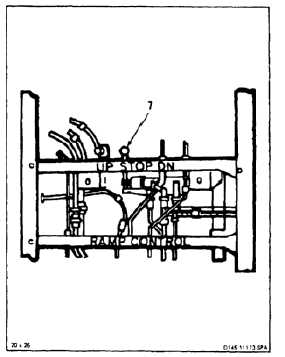

6.

Position ramp control (7) to UP.

7.

Apply hydraulic power. Increase test stand

pressure until ramp starts to close. When ramp

is about 1 inch from fully closed, set control (7)

to STOP.

NOTE

Bleed hose must be below fluid level

during bleeding.

8.

Set control (7) to DN. Lower ramp slowly by

operating control between DN and STOP.

9.

Repeat steps 6, 7, and 8 until fluid from hose

(3) is air free.

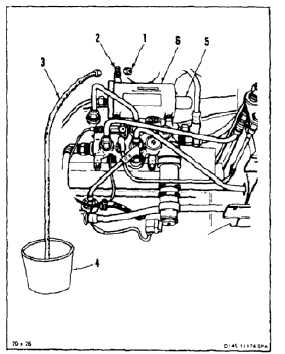

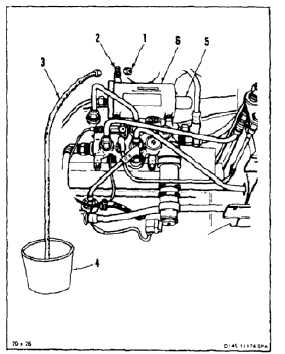

10.

Repeat step 8. Close valve (2).

11.

Repeat step 6. Check rod (5) extends about 4.2

inches from cylinder (6).

12.

Repeat step 8. Check rod (5) retracts.

13.

Disconnect hose (3) from valve (2). Use cloths

(E120) for spilled fluid.

14.

Install cap (1) on valve (2).

15.

Remove hose (3) and container (4).

NO BREAK - WORK HARDER

NO BREAK - WORK HARDER

NO BREAK - WORK HARDER

FOLLOW-ON MAINTENANCE:

Close cargo ramp (TM 55-1520-240-T).

Disconnect hydraulic test stand from ground service

panel (Task 1-38).

Remove electrical power (Task 1-37).

Set ramp switch to OFF.

END OF TASK

7-1254