TM 55-1520-240-23-5

6-19

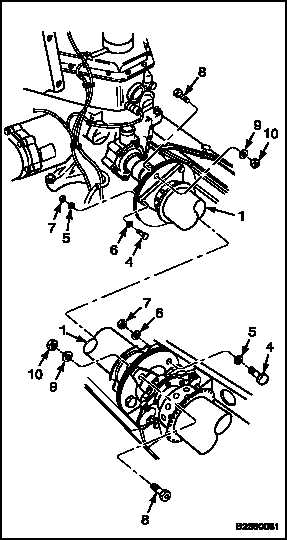

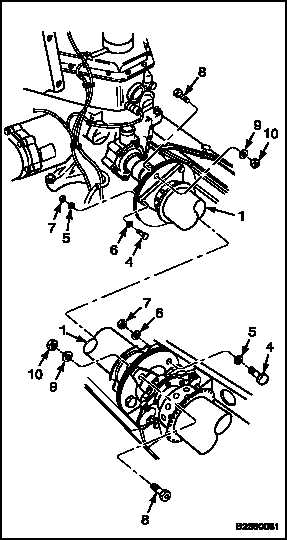

INSTALL NO. 7 DRIVE SHAFT (Continued)

6-19

NOTE

Special washers are installed against

adapter assemblies.

2.

Coat thread of six bolts (4) with oil (E254/E254.1).

Install three bolts, head forward, special washers

(5), washers (6), and nuts (7) at each end of

shaft (1).

CAUTION

Do not allow bolts to turn when

torquing nuts. If bolts turn, bolts and

plates can be damaged.

NOTE

If nuts do not meet friction torque,

they must be replaced.

3.

Hold head of bolts (4) with wrench. Check nuts

for friction torque of at least 24 inch-pounds.

4.

Torque nuts to 1000-1100 inch-pounds.

5.

Coat two adapter assembly bolts (8) with oil

(E254/E254.1). Install bolts, special washers (9),

and nuts (10).

CAUTION

Do not allow bolts to turn when

torquing nuts. If bolts turn, bolts and

adapter assembly can be damaged.

NOTE

If nuts do not meet friction torque,

they must be replaced.

6.

Hold head of bolts (8) with wrench. Check nuts

for friction torque of at least 24 inch-pounds.

7.

Torque nuts to 1000-1100 inch-pounds.

INSPECT

FOLLOW-ON MAINTENANCE:

Check rotary-wing blade phasing (Task 6-27.1).

Close forward drive shaft tunnel No. 6 drive shaft

cover (Task 2-2).

Close pylon lower fairing (Task 2-2).

Close pylon hinged fairing (Task 2-2).

Install cabin tunnel smoke baffle (Task 2-170.1).

Perform a combining transmission oil cooler fan

vibration check (TM 1-6625-724-13&P).

END OF TASK

6-59