TM 55-1520-240-23-5

6-144

INSTALL AFT TRANSMISSION OIL COOLER FAN

(Continued)

6-144

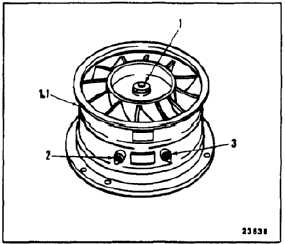

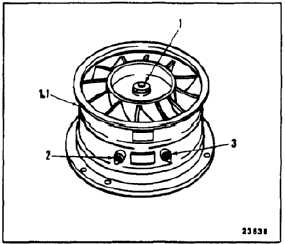

1.

Check the torque of the fan retaining nut (1).

Torque nut to 400 inch-pounds.

Do not overgrease. Do not block vent

fitting (3). Stop grease application

as soon as clean grease comes out

of vent fitting.

1.1.

Apply grease (E190) to fan (1.1) at fitting (2) until

clean grease comes out vent (3). Use hand

lubricating gun.

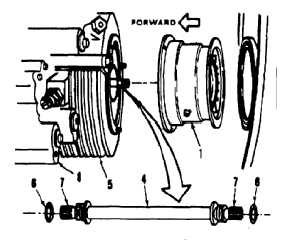

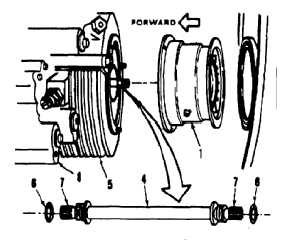

2.

Remove drive shaft (4) from oil cooler (5).

Remove packings (6) from each end of shaft.

Dry cleaning solvent (E162) is

flammable end toxic. It can irritate

skin and cause burns. Use only in

well-ventilated area, away from heat

and open flame. In case of contact,

immediately flush skin or eyes with

water for at least 15 minutes. Get

medical attention for eyes.

3.

Clean splines (7) at both ends of shaft (4). Use

solvent (E162) and clean cloths (E120). Wear

gloves (E186).

3.1.

Inspect splines (7) on drive shaft (4) for wear. If

splines are worn, proceed as follows:

a.

Place a 6 inch metal ruler or equivalent

straightedge along the length of splines (7),

with ruler spanning worn area.

b.

Measure the depth of wear below the face of

the spline. Use a feeler gage.

c.

If spline wear at fan end exceeds 0.020 inch,

replace drive shaft (4) and fan (1.1).

d.

If spline wear at transmission end exceeds

0.020 inch, perform steps 6 thru 9. Replace

aft transmission (8). (Refer to Tasks 6-92 and

6-97.)

e.

The 0.020 inch maximum wear is with no

raised material on both ends of the quill

shaft’s flange. If raised material is found,

remove the material by hand, polishing the

affected area with an oil wet scotchbrite pad.

Remove a minimum amount of material. Do

not exceed 0.020 inch maximum depth.

f.

If wear is less than 0.020 inch, all parts are

satisfactory for continued use.

4.

Install packings (6) on each end of shaft (4).

5.

Pack splines (7) and mating splines in

transmission (8) and fan (1.1) with grease

(E190.1).

6-510