TM 55-1520-240-23-5

6-58

INSPECT FORWARD AND AFT ROTOR SHAFT

(Continued)

6-58

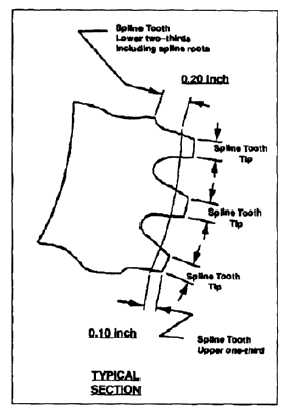

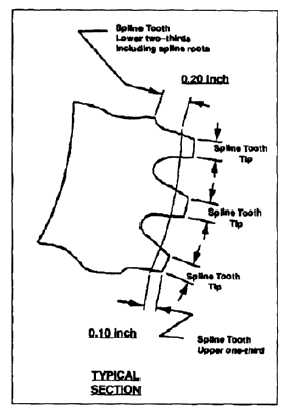

NOTE

The sensitivity to damage of the spline

teeth differs among the three areas.

The spline tooth lower two thirds,

including spline roots, is the highest

loaded and most sensitive of the three

areas. The spline tooth upper one

third is less sensitive than the lower

two thirds. The spline tooth tips are

the least sensitive of the three areas.

(a)

Spline tooth lower two thirds including

spline roots (reference 0.20 inch). No

pitting corrosion, nicks or scratches

are allowed in this area. A light visual

indication of wear or wear step is

permitted provided it does not exceed

0.0010 inch depth.

(b)

Spline tooth upper one third (reference

0.10 inch). Nicks, dings, or scratches

are allowed in this area up to a depth

of 0.0020 inch. No pitting corrosion

is allowed that exceeds 0.0010 inch.

Lightly blend nicks, dings, scratches,

and pitting corrosion.

(c)

Spline tooth tips. Pitting corrosion,

nicks, dings, or scratches are allowed

in this area up to a depth of 0.010

inch. Lightly blend and polish tip.

Remove any sharp edges from nicks,

dings, and scratches.

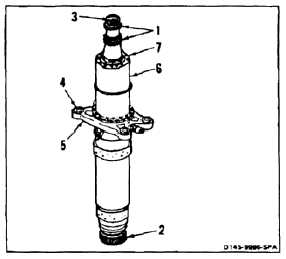

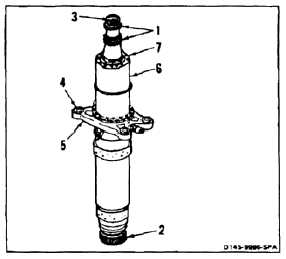

2.1.

Inspect fwd rotor shaft for cracks. If a crack is

suspected, refer to TM 1-1520-253-23.

3.

Check thread (3) for damage. There shall be

no damage.

4.

Inspect bushings (4) at top and bottom of four

mounting holes in support (5). There shall be no

cracks, wear, or other damage.

5.

Check support (5) for oil leakage. There shall

be no oil.

5.1.

Inspect aft rotor shaft for cracks. If a crack is

suspected, refer to TM 1-1520-253-23.

6.

Inspect slider shaft (6) for damage. Damage shall

not exceed the limits specified in Task 6-52.1.

7.

Inspect seal. Ensure that a minimum clearance

of 0.050 inch between the rubber seal and the

surface of the rotor shaft. If a minimum clearance

does not exist between the shaft and seal,

inspect the seal for deterioration and damage.

There shall be no damage.

FOLLOW-ON MAINTENANCE:

None

END OF TASK

6-226