TM 55-1520-240-23-5

6-38.1

REPAIR FORWARD TRANSMISSION SLIDER SHAFT

(Continued)

6-38.1

1.

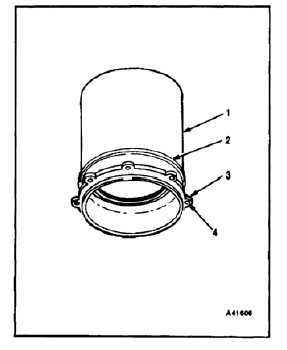

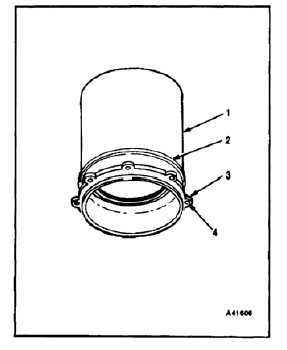

Clean oil and grease from slider shaft (1). Use

naphtha (E245) and clean cloths (E120). Wear

gloves (E184.1).

2.

Inspect surface of slider shaft (1) for nicks,

scratches, and minor pitting or corrosion of

coating. Observe the following definitions:

a.

Nick — A surface indentation with a sharp

crease at the bottom. Surface finish is not

broken. Caused by pressure or impact from a

hard object with a sharp edge.

b.

Scratch — A light, narrow mark on the

surface. Surface finish is broken, but not

removed. Caused by a hard, sharp particle

moving across the surface.

c.

Pit — A small irregular cavity where material

is removed from the surface. Usually

caused by corrosion. Pits are usually dark

in appearance.

d.

Corrosion — A broken or pitted surface,

discolored around the edge. Corrosion is

caused by chemical action.

3.

Note extent and location of damage:

NOTE

Limits in this step refer to depth of

damage after rework.

a.

Depth of damage above flange (2) (bearing

surface) shall not be more than 0.020 inch.

Depth of damage below flange shall not be

more than 0.025 inch.

b.

Damage shall not extend from shaft surface

to mounting flange (3).

c.

Damage on mounting flange (3) shall not be

closer than 1.00 inch to any mounting hole

(4).

6-131