TM 55-1520-240-23-4

5-9

INSTALL ROTARY-WING HEAD

(Continued)

5-9

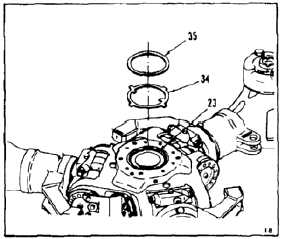

27.

Install tang washer (34) on nut (23).

Do not file tang washer to make it

fit. Filing can cause tangs to break

causing loss of helicopter and loss

of life.

28.

If tang washer (34) cannot be seated in any

position, repeat steps 12 thru 27. Increase

torque of step 21 to 5750 foot-pounds to permit

washer to be seated.

29.

If tang washer (34) cannot be seated in any

position, repeat steps 18 thru 27, increasing

torque to 6000 foot-pounds.

Before backing off torque, the three

reaction hooks must be reversed so

that the REMOVAL side faces out,

as in Task 5-8; otherwise, injury to

personnel and damage to equipment

may occur.

30.

If tang washer (34) still will not seat, back off

nut (23). (Refer to Task 5-8.) Repeat steps 18

thru 27, torquing nut to 5600 foot-pounds and

other in-between torques as needed for washer

alignment.

31.

Install retaining ring (35) in groove of nut (23).

INSPECT

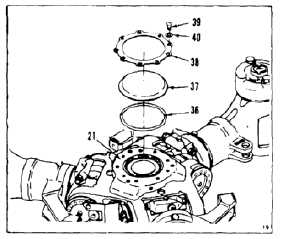

32.

Install packing (36) on hub oil tank (21).

33.

Position cover (37) on hub oil tank (21).

34.

Position retainer (38) on cover (37). Install nine

screws (39) and washers (40). Torque screws to

23 inch-pounds.

5-66