TM 55-1520-240-23-4

5-9

INSTALL ROTARY-WING HEAD (Continued)

5-9

WARNING

Dry cleaning solvent (E162) is

flammable and toxic. It can irritate

skin and cause burns. Use only in

well-ventilated area, away from heat

and open flame. In case of contact,

immediately flush skin or eyes with

water for at least 15 minutes. Get

medical attention for eyes.

WARNING

Check rotor hub data plate serial

number to ensure that it does not read

UW3018. If rotor hub (S/N UW3018)

is found, do not install. Immediately

contact the technical point of contact

in TB 1-1520-240-20-134.

CAUTION

Horizontal hinge pins with serial

numbers of UW2407 and prior that do

not have a suffix "A" vibro engraved

after the serial number and with total

time since new of 4800 flight hours

or more must be replaced.

NOTE

Procedure is similar to install

rotary-wing head with or without

blades attached. Installation of

rotary-wing head with blades removed

is shown.

Task is similar for forward and aft

rotary-wing heads. Differences are

noted in text. Forward rotary-wing

head can be installed with forward

transmission package in workstand.

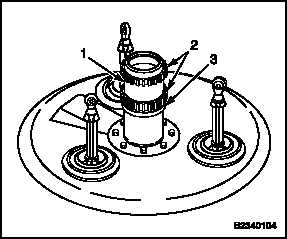

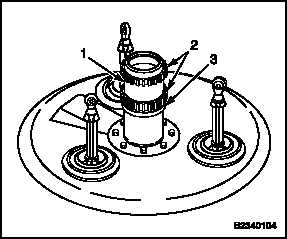

1.

Remove barrier material from driveshaft (1).

Clean splines (2). Use cloth (E120) damp with

dry cleaning solvent (E162). Wear gloves (E186).

Wipe splines dry. Use clean cloth (E120). Apply

thick coat of grease (E190) evenly to splines.

Use brush (E86).

1.1.

Check weight cavity drain hole in pitch-varying

housing to ensure it is clear of debris. Use pipe

cleaner (E469).

2.

Check that spacer (3) is installed on shaft (1) of

forward transmission.

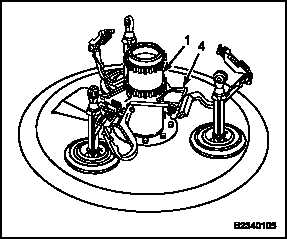

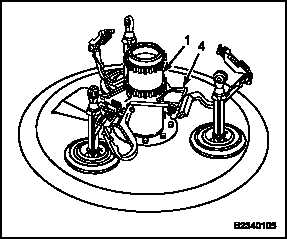

3.

Check that centrifugal droop stop (4) is installed

on shaft (1) of aft vertical shaft.

5-56

Change 2