TM 55-1520-240-23-4

5-6.1

INSPECT ROTARY-WING HEAD OIL TANKS FOR ALLOWABLE OIL

LEAKAGE

(Continued)

5-6.1

NOTE

Due to time required, it is best to

perform this inspection during a

scheduled flight of at least two hours.

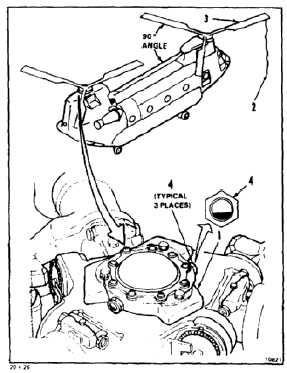

HUB OIL TANK

1.

Service hub oil tank (1) (Task 1-55).

2.

Connect battery (Task 1-39).

3.

Have pilot perform a 30 minute ground run (TM

55-1520-240-10).

4.

Disconnect battery (Task 1-39).

5.

Install tiedown line (2) on one forward blade (3)

(Task 1-26).

NOTE

Blades must be in proper position to

get a correct reading of oil level.

6.

Using tiedown line (2), turn blades (3) so that

one is positioned at a 90º angle to left or right

side of helicopter.

7.

Check oil level in sight gage (4) next to blade (3)

that is at 90º angle. If oil is at bottom of gage,

leakage is excessive.

8.

If leakage is excessive, horizontal hinge pin

seals are defective. Replace seals (Tasks 5-42

and 5-43).

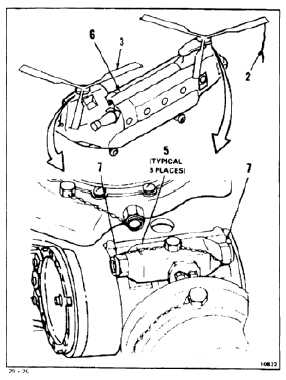

PITCH BEARING OIL TANK

9.

Service pitch bearing oil tank (5) (Task 1-56).

10.

Connect battery (Task 1-39).

11.

Have pilot perform a 30 minute ground run (TM

55-1520-240-10).

12.

Disconnect battery (Task 1-39).

13.

Install tiedown line (2) on one forward blade (3)

(Task 1-26).

NOTE

Blades must be in proper position to

get a correct reading of oil level.

14.

Using tiedown line (2), turn blades (3) so that

blade of tank (5) to be checked is over drive shaft

tunnel (6).

15.

Check oil level in sight gage (7) on each side of

oil tank (5) of blade (3) over tunnel (6). If average

level at two gages is at bottom of sight gage,

leakage is excessive.

16.

If leakage is excessive, pitch-varying housing oil

seals are defective. Replace seals (Tasks 5-24

and 5-25).

5-37