TM 55-1520-240-23-4

5-84

INSTALL ROTARY-WING BLADE

(Continued)

5-84

Lower vertical pin nut must be

installed and torqued before upper nut

is installed. Installing upper nut first

can cause damage to pin.

12.

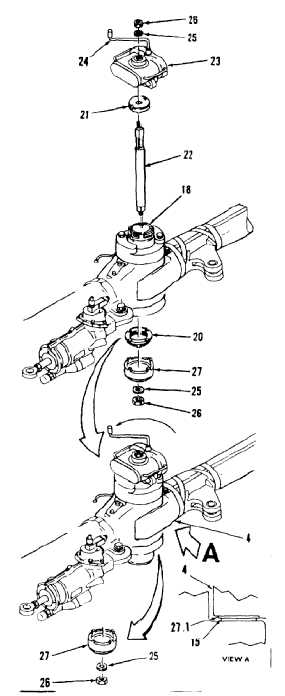

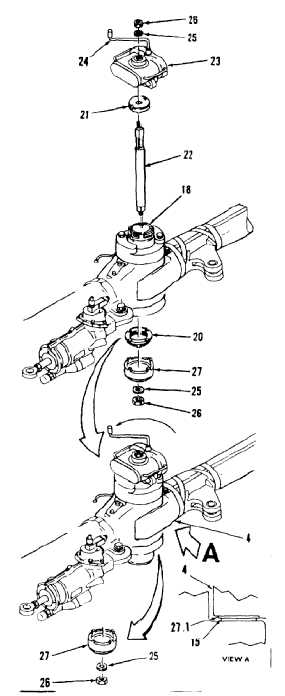

Install lower vertical pin nut (20) as follows:

a.

Position pitot socket (21) on drive bar (22).

Position drive bar through vertical pin (18).

Have helper support drive bar (22).

b.

Install torque wrench (T23) (23) on drive bar

(22). Turn handle (24) in either direction until

wrench is seated on pitot socket (21).

c.

Install washer (25) and nut (26) on drive bar

(22). Have helper release bar.

d.

Install lower nut (20) on pin (18) and

hand-tighten.

e.

Install spanner socket (27), on drive bar (22),

and engage with lower pin nut (20). Install

washer (25) and nut (26).

f.

Adjust upper and lower nuts (26) until drive

bar (22) is seated in spanner socket (27).

Torque wrench (T23) must not turn

during installation of lower nut.

Equipment can be damaged.

g.

Turn handle (24) counterclockwise. Torque

lower nut (20) to 275 foot-pounds. Check

gap between inner bearing race (15) and

liner (27.1) of blade (4). Gap shall not extend

more than 50 percent of contact surface.

NOTE

No limit on gap depth.

INSPECT

h.

Remove nut (26), washer (25), and spanner

socket (27).

5-514