TM 55-1520-240-23-4

5-5

PRESSURE TEST ROTARY-WING HEAD SEALS AND PACKINGS

(Continued)

5-5

Do not exceed 20 psi when testing

seals. High-pressure air will damage

seals.

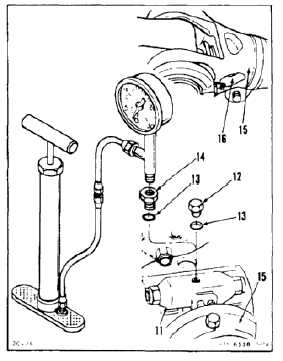

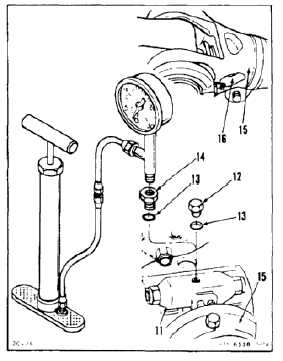

9.

Pressurize tank (11) to 3 to 5 psi. Maintain

pressure for 10 minutes. Check inboard end of

pitch housing (15) for oil leaks. Check oil hole

(16) at tie-bar hole area under pitch housing.

There shall be no leaks.

10.

Increase pressure in tank (11) to 15 to 20 psi.

Maintain pressure for 5 minutes. Check inboard

end of pitch housing (15) for oil leaks. Check

oil hole (16) at tie-bar hole area under pitch

housing. There shall be no leaks.

11.

Loosen pressurizing filling (14) just enough to

bleed pressure. When gage pressure is 0 psi,

remove filling and packing (13).

12.

Install packing (13) and plug (12). Torque plug to

25 inch-pounds. Lockwire plug. Use lockwire

(E231).

INSPECT

TEST VERTICAL HINGE PIN OIL TANK SEALS AND

PACKINGS

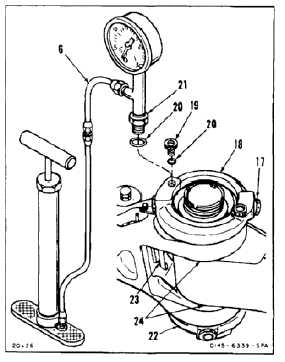

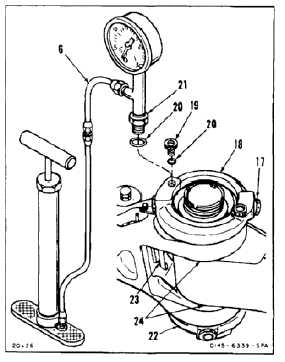

13.

Check oil level in sight indicator (17). Service oil

tank (18) if needed (Task 1-59).

14.

Remove one filler plug (19) and packing (20).

Install pressurizing fitting (21) and packing in

tank (18). Connect test setup (6) to pressurizing

fitting.

Do not exceed 20 psi when testing

seals. High pressure air can damage

seals.

15.

Pressurize tank (18) to 3 to 5 psi. Maintain

pressure for 10 minutes. Check tanks (18 and

22), oil manifold (23), and lugs (24), for oil leaks.

There shall be no leaks.

16.

Increase pressure in tanks (18 and 22) to 15 to

20 psi. Maintain pressure for 5 minutes. Check

tanks, oil manifold (23), and lugs (24), for oil

leaks. There shall be no leaks.

5-29