TM 55-1520-240-23-4

5-72

TRAILING EDGE REPAIR — MAJOR DAMAGE

(Continued)

5-72

Adhesive used in the manufacturing of

some fiberglass rotor blades contain

asbestos. During blade repair, strict

adherence to all safety procedures

when working with asbestos must

be complied with (applies to blade

serial number A-1-0001 to 1465 and

A-2-0001 to 1473 only).

NOTE

There is no limit to the number of

repairs that can be made. Minimum

edge-to-edge distance between

repairs shall be 6 inches.

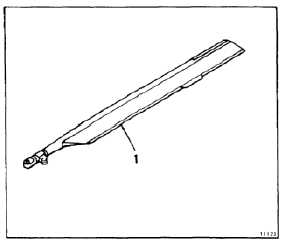

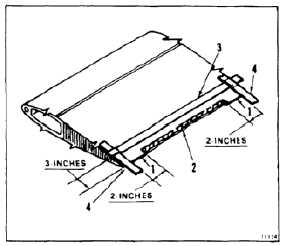

1.

Check location and size of major damage to

trailing edge (1).

a.

Reparable damage of trailing edge (1)

shall not exceed 1-1/4 inches chordwise.

Spanwise damage is not limited.

b.

Damage greater than 1-1/4 inches chordwise

requires rejection of the rotor blade.

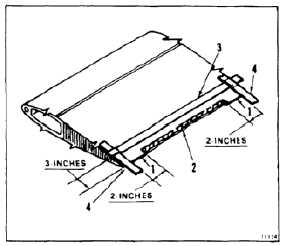

2.

Mask damaged area (2) as follows:

a.

Apply tape (E388) (3) spanwise 3 inches

from trailing edge (1).

b.

Apply tape (E388) (4) chordwise 2 inches

from edges of damaged area (2).

3.

Remove finish from area inside tapes (E388) (3

and 4). Use abrasive paper (E7) and sanding

block. Soften finish, if needed. Use acetone

(E20). Remove tapes (3 and 4). Wear gloves

(E186).

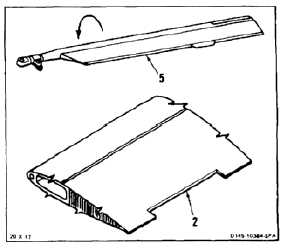

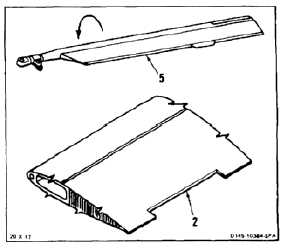

4.

Have helpers turn blade (5) upside down.

5.

Draw rectangle outline around damaged area

(2). Do not exceed dimensions in step 1.

Do not cut forward of guide line around

damaged area. Cutting chordwise

farther than line will damage blade

structure and require rejection of the

blade.

6.

Cut inside guide line to remove damaged area

(2). Use a saber saw or hacksaw.

5-405