TM 55-1520-240-23-4

5-69

REPAIR BLADE FAIRING — PARTIAL DEPTH

(Continued)

5-69

NOTE

Working life of adhesive is 30

minutes.

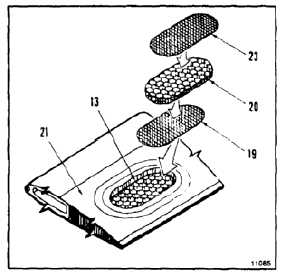

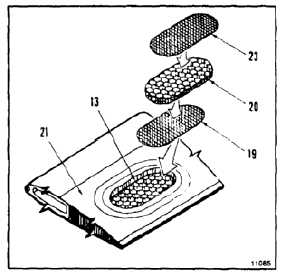

27.

Apply adhesive (E40, E41, E43, or E47.1) to one

side of scrim cloth (E325) (19). Use stiff brush.

28.

Position scrim cloth (E325) (19) in cutout (13)

with adhesive down.

29.

Coat top of scrim cloth (E325) (19) and walls of

cutout (13). Use adhesive (E40, E41, E43, or

E47.1).

30.

Align matchmarks on core (20) and skin (21).

Press core until it seats completely.

31.

Apply adhesive (E40, E41, E43, or E47.1) to one

side of patch (22) and 1 inch outside of cutout

(13). If fiberglass laminate (E168.1) is used,

apply adhesive so outer edges of patch curl

towards the blade.

32.

Center patch (23) over core (20). Position patch

with fibers at 45º to chord. Press firmly onto skin

(20).

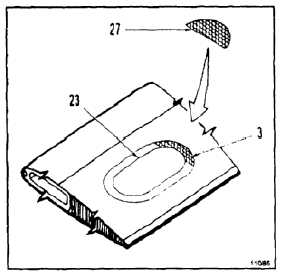

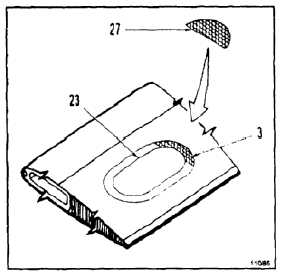

33.

If wire mesh diverter damage is more than 1

square-inch, replace mesh (23) as follows:

a.

Cut piece of mesh (E453) (27) to cover patch

(23) and exposed mesh (3).

b.

Brush thin coat of adhesive (E40 or E41) over

patch (23) and damaged mesh (3).

c.

Position mesh (E453) (27) over patch (23).

Seat firmly.

NOTE

All blade repairs, weight adjustment,

painting, or balancing will be recorded

on rotor blade DA Form 2408-16,

each blade requires a separate form.

If the rotor blade does not have a DA

Form 2408-16, one must be prepared

and all actions recorded, as example;

location of repair, size of repair,

weight of repair, and required weight

adjustments for track and balance.

5-376