TM 55-1520-240-23-4

5-52

CENTRIFUGAL DROOP STOP FUNCTIONAL CHECK

(Continued)

5-52

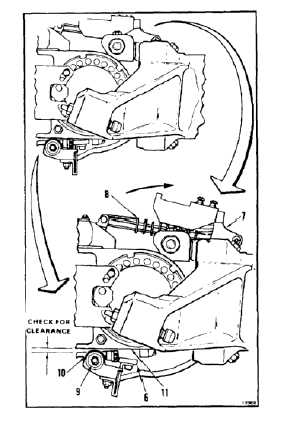

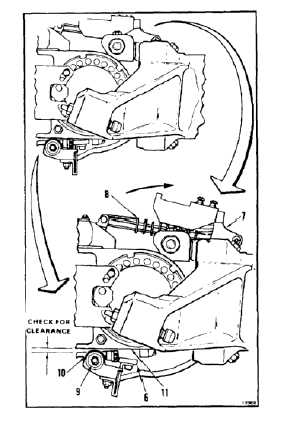

Balancing arms must move freely

when blade is raised. Fuselage can

be damaged if there is interference

with balancing arm operation.

3.

Move balancing arm (7) outward as far as it

will go. Check that spring (8) is clear of other

parts. There shall be no interference with spring

operation.

4.

Check pivot bearing (9) for binding. There shall

be no binding.

5.

Check for interference at interposer block (6).

There shall be no interference.

6.

Check that there is clearance between balancing

arm pivot lugs (10) and bottom of hub (11). If

there is clearance, go to step 9. If there is no

clearance, perform steps 7 thru 8.

7.

Remove centrifugal droop stop assembly (Task

5-54).

7.1.

Remove enough metal from top of lugs (10) to

provide clearance. Use smooth file.

7.2.

Finish reworked area of lugs (10) as follows:

Alodine (E65) is an oxidizer. Discard

cloths which contain this material in a

separate container. If discarded with

cloths contaminated with acetone,

MEK, or other organic solvents,

combustion can result. In case of

contact, immediately flush skin or eyes

with water for at least 15 minutes.

Get medical attention for eyes.

a.

Mix 3 ounces of alodine powder (E65) with

1/2 ounce of concentrated nitric acid (E22).

Add mixture to 1 gallon of water.

b.

Apply alodine solution to reworked area of

lugs. Wear gloves (E184.1).

c.

Rinse surface with cold water and let air dry.

5-236