TM 55-1520-240-23-4

5-25

INSTALL PITCH HOUSING SEALS

(Continued)

5-25

NOTE

Task is same to install seals in all six

pitch-varying housings.

Adhesive (E63.1) or sealant (E340.3)

is authorized specifically for the

installation of pitch housing seal.

1.

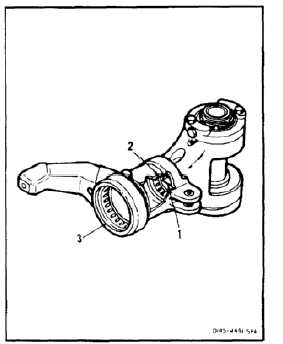

Clean inside of housing (1), outboard of seal seat

(2). Use cloth (E120) moist with solvent (E161).

Wear gloves (E184.1).

Do not contaminate bearings. Dirt can

damage bearing surfaces.

2.

Clean oil or dirt from seal seats (2 and 3). Use

cloth (E120) damp with methyl-ethyl-ketone

(E244). Wear gloves (E184.1).

Do not block drain hole. Oil can not

drain freely if hole is blocked.

2.1.

Inspect seats (2 and 3) (Task 5-24.1).

3.

Prime inside of housing (1), outboard of seal seat

(2). Use epoxy primer (E292.1). Wear gloves

(E184.1).

INSTALL OUTBOARD SEAL

Do not allow adhesive to contact

bearing. Adhesive can adhere to

bearing.

NOTE

All sealants and adhesives have

different cure times. When using

sealants and adhesives, the directions

on the container are to be considered

minimum cure time before full

operation of the aircraft.

4.

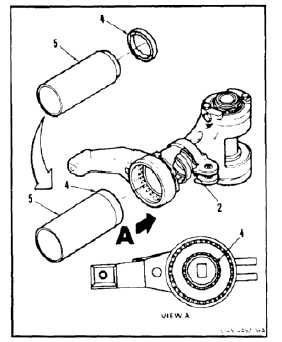

Apply adhesive (E63.1) or sealant (E340.3) to

outboard seal seat (2).

5.

Position outboard seal (4) on drift (T11) (5).

6.

Install outboard seal (4) in seal seat (2). Remove

drift (T11) (5).

7.

Wipe off excess adhesive around outboard seal

(4). Use cloth (E120) damp with solvent (E162).

Wear gloves (E184.1).

5-135