TM 55-1520-240-23-4

5-20

REPAIR PITCH BEARING OIL TANK (AVIM)

(Continued)

5-20

Dry cleaning solvent (E162) is

flammable and toxic. It can irritate

skin and cause burns. Use only in

well-ventilated area, away from heat

and open flame. In case of contact,

immediately flush skin or eyes with

water for at least 15 minutes. Get

medical attention for eyes.

Metallic dust and paint chips can block

oil passages and damage rotary-wing

head. Tank openings must be plugged

before reworking or refinishing tank.

NOTE

Procedure is same to repair all six

pitch bearing oil tanks.

1.

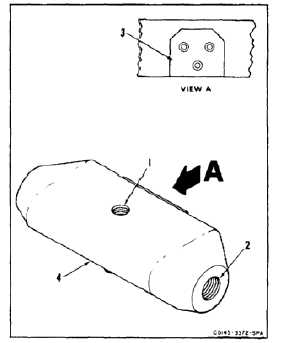

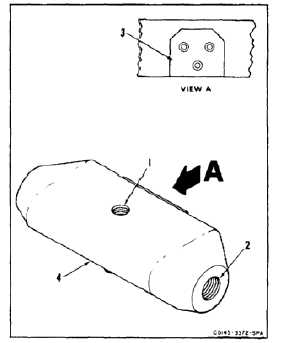

Plug filler plug hole (1) and both sight indicator

holes (2). Use caps or plugs. Mask mounting

surface (3) near rework and refinish area. Use

masking tape (E388).

2.

Clean mounting surface of tank (4). Use plastic

or aluminum scraper and cloths (E120) damp

with solvent (E162). Wear gloves (E184.1).

3.

Blend scores, nicks, or gouges on tank (4).

Damage limit is 0.020 inch in depth by 2.5

inches in length. Blend to width at least 10 times

depth of damage. Use crocus cloth (E122).

5-101