TM 55-1520-240-23-3

3-41

REPAIR AFT LANDING GEAR SHOCK STRUT (AVIM)

(Continued)

3-41

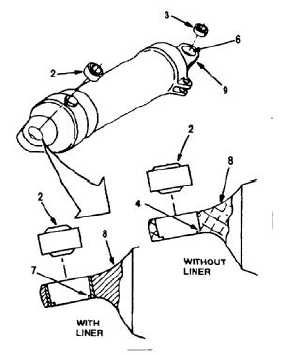

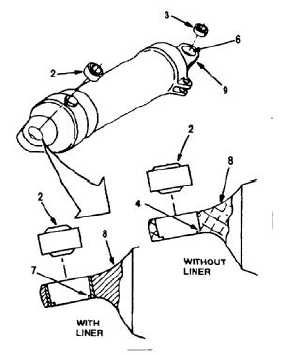

INSTALL BEARINGS

NOTE

Cap lug bearing may be installed

within liner or directly within cap lug

bore. Piston bearing is installed

directly within piston lug bore.

9.

Clean bearings (2 and 3) and mating surfaces of

cap bore (4) or liner (7) and piston bore (6). Use

acetone (E20). Wear gloves (E184.1).

Sealant (E345.1) can irritate skin and

cause burns. Avoid contact with skin,

eyes, or clothing. In case of contact,

immediately flush skin or eyes with

water for at least 15 minutes. Get

medical attention for eyes.

10.

Apply sealant (E345.1) to mating surfaces of

bearings (2 and 3), bore (4) or liner (7) and bore

(6) (MIL-R-46082). Wear gloves (E184.1).

11.

Install bearing (2) in bore (4) or liner (7). Install

bearing (3) in bore (6). Use arbor press (TM

55-1500-322-24). Installed bearings shall be

flush with lugs (8 and 9).

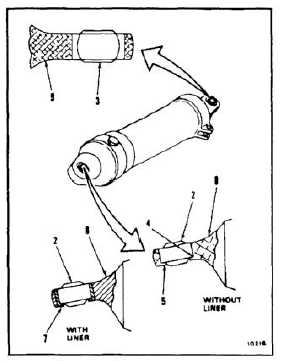

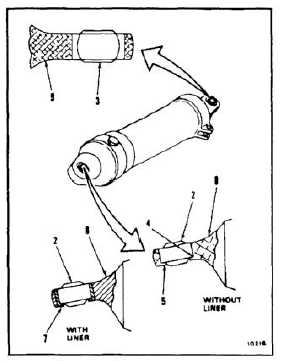

INSPECT

12.

Stake bearing (2) or liner (7) to cap lug (8) as

follows:

a.

Bearing (2) in bore (4): Roller stake cap lug

(8) over bearing on side opposite shoulder

(5) only. Use Roller Swaged Housing Staking

method (TM 55-1500-322-24). Use roller

staking kit (T169).

b.

Bearing (2) in liner (7): Roller or impression

stake liner to cap lug (8) on side with

shoulder in liner (7). On opposite side,

swage liner to both bearing and cap lug.

Use Roller Swage Sleeve Staking method

or Circumferential Line Impression Staking

method (TM 55-1500-322-24). Use roller

staking kit (T169) where applicable.

13.

Stake bearing (3) to piston lug (9) with Outer Ring

Groove Staking method (TM 55-1500-322-24).

INSPECT

3-103